Valve, control and container boxes for Lindner & Fischer

Tank and silo vehicle construction with expertise for daily use

For more than 30 years Lindner & Fischer Fahrzeugbau GmbH has been building tank and silo vehicles at its locations in Langenau, Bad Fallingbostel and Seefeld near Berlin.

Around 130 employees manufacture customised vehicles both for individual orders and in large quantities. The focus is always on the customer’s wishes. Innovative problem solutions, practical concepts combined with state-of-the-art technology characterise the market position in the national and international environment.

Special attention is paid to the economic efficiency of the vehicles. The shorter the service life, the better for the operating company. It is important to avoid unnecessary journeys when refuelling, for example with heating oil or supplying wood pellets – whether for private individuals or companies – so that the vehicles can drive to the next customer as quickly as possible.

Boxes with brains

The valve, control and container boxes play an important role here. Depending on the design, they accommodate all the necessary equipment in clean and spatially separated units, from hoses, connections and pumps to the electronic components of the tank superstructure with limit value transmitters, control blocks and measuring instruments to the mobile office with printer. This enables the tanker driver to hand over the delivery note including invoice with accurate information to the customer and, if necessary, to make a direct payment transaction.

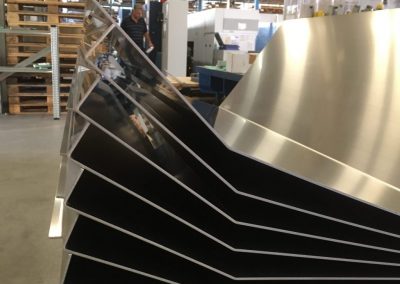

Since 2018 Ferrum Lasercut has been supplying Lindner & Fischer with all sheet metal for the new modular system of modular fittings, operating and container boxes. These boxes are lasercut, edged and welded from aluminium without exception, so that the well thought-out special solutions from L+F with their almost unlimited equipment variants enable drivers to work ergonomically and efficiently.

The quality of the crates is decisive. They are exposed to constant stress. The flaps and doors are opened and closed frequently, at the same time they should not hinder pedestrians and other road users. The solution: the box doors swing open upwards. In addition, the operators often have to reach into the crates. To prevent injuries as much as possible, all edges are burr-free and rounded.

Arguments in favour of Ferrum Lasercut are the fast preparation of quotations, flexible, customer-oriented production processes and last but not least the reliable and punctual delivery. Ferrum benefits from the ability to respond to the different requirements of the customer in the shortest possible time on the one hand, and on the other hand, the long experience in the production of prototypes and single pieces up to series counts.

For Lindner & Fischer, this means being able to equip more than 200 tank and silo vehicles per year with at least three individual fittings, operating and container boxes per vehicle.

- Customer: Lindner & Fischer Fahrzeugbau GmbH

- Project title: Container Boxen

- Metal works: Lasering, bending, welding

- Materials: Aluminium

- Link: www.lindner-fischer.com