News at Ferrum Lasercut GmbH

PREMIERE!

Ferrum Lasercut GmbH exhibits at the MUTEC in Leipzig.

MUTEC is the International Trade Fair for Museum and Exhibition Technology.

Here decision makers, planners and employees from museums, galleries and collections as well as responsible persons from science centers, theaters, stages and public institutions meet. They use the fair as an information platform with regard to the current state of the art in exhibit construction, climate and measurement technology, ticketing, equipment and much more.

Ferrum has been working with a number of exhibition makers, scenographers and conceptual designers for a long time. This has now led us to go one step further.

Our products can be found as exhibits in museums or as works of art in collections all over the world. Often “our” work can be found in very exposed places in a multitude of museums, exhibitions, galleries, but most of the time it is not noticed, because the focus is on what our work makes suitable for exhibition.

We often build metal structures that serve as the basis for the actual exhibits, e.g. substructures for touch tables, wayfinding systems, housings for entry systems. Or we produce panels for multimedia components of various kinds and – now and then – complete and complex exhibits.

At the joint stand with werk5 and Interactive Scape we would like to introduce ourselves personally to the makers and planners of exhibitions.

If you want to know more, just visit us from November 24-26 in Hall 2, Stand I46 at the Leipzig Fair. All others can find out more at www.ferrum-lasercut.de.

See you soon.

Knowhow from practice for selected startups

MotionLab.Berlin is an institution for hardtech startups

MotionLab.Berlin offers startups, freelancers, artists, students, and SMEs plenty of opportunities, support, machines, and space to try out ideas, explore the entrepreneurial potential of their respective ideas, produce prototypes and small series, or in short: turn their own product idea into reality.

For startups from the manufacturing industry, production, mobility and logistics, there is now the MakeUp Industrial Tech Accelerator. This is a program that provides even more intensive support for startups in the areas of hard tech (software/hardware), IIoT (Industrial IoT), AI (artificial intelligence) and robots & cobots.

The selection process for the MakeUp Industrial Tech Startup Accelerator Startups has now been completed. Participating startups receive an investment of 100,000 euros, their own workshop and access to a large network of industry experts and mentors who strive to help the startups advance within the 8-month program.

Expert knowledge in the Accelerator Program

Here, Uwe Glasenapp, in the function of an “Accelerator”, plays an essential role in all questions related to the topic of metal.

The managing director of Ferrum Lasercut GmbH has made it his business to support young entrepreneurs, especially in the field of metal working and processing. The graduate physicist throws his many years of experience in manufacturing technology, automation and in his own company into the race, both in theory and in practice. Start-ups can count on him for a wide range of support. Starting with general product planning, design and its actual feasibility, sensible manufacturing processes as well as the opportunities and limits of the material, possible optimisation potentials and finally, of course, the realisation from the first unit as a prototype as well as the scalability into series production.

Several startups from the MotionLab, especially those dealing with (urban) mobility, have already been able to realize their prototypes with Uwe Glasenapp’s support, benefit from his expertise, test their ideas in hardware, optimize them and turn them into near-series (not to say: production-ready) product concepts.

The Accelerator program has started on 10/31/2022 with the selected startups. For more information, please visit the Industrial Tech landing page of MotionLab.Berlin or www.ferrum-lasercut.de.

Stay up to date!

What does Corona have to do with steel?

Before Christmas, prices for steel, stainless steel and aluminum were still subject to the usual market fluctuations and – viewed over the year – were reasonably stable.

This changed at the beginning of December. Since then, prices have skyrocketed. Steel has become up to 70% more expensive, aluminum by more than 40%. For stainless steel, the price increase is between 25% and 30%.

Market balance out of kilter

The reason for this lies in the accumulation of several problem areas.

Firstly, the current pandemic situation has meant that at times there has been no or very little demand for steel, stainless steel and aluminum on the market. As a result, steel producers have shut down some of their blast furnaces and also stopped ordering raw materials such as iron ore, bauxite and hard coal. Raw materials which are not usually stored on the doorstep but have long procurement times, such as iron ore from Australia at 6-8 weeks. Even if the steel industry decides to restart the blast furnaces in view of the current economic situation, it will take around a quarter of a year, provided all the necessary materials are on site.

A second reason for the steel price development is the automotive industry. At the start of the crisis, manufacturers filled their warehouses with steel, stainless steel and aluminum, resulting in a significant shortage of material on the market.

Fundamental restructuring and new technologies in steel production

Thirdly, the steel industry is facing drastic changes and high investments. By 2050, steel production is to become climate-neutral. The aim is to use hydrogen to make steel green and prevent the emission of millions of tons of the climate-damaging greenhouse gas CO2. To achieve this goal, the steel production process is being fundamentally reformed, rethought and consistently developed.

By 2030, one of the largest steel producers in Europe will have to spend around 15 billion euros on this technological revolution. Money that first has to be earned in order to be able to offer three million tons of climate-neutral steel as early as 2030 and thus save six million tons of CO2.

Effects of global economic trends on companies like Ferrum Lasercut

Overall, the current supply and price situation for steel, stainless steel and aluminum is subject to the play of forces on the global market. For companies like Ferrum Lasercut and its customers, the situation is extremely unsatisfactory. We inquire about each sheet metal on a project-by-project basis with our steel suppliers. Some material grades and thicknesses are currently no longer available at all, others are only available in 2-3 weeks, while still others score with a delivery time of 24 hours. Unfortunately, the availability does not follow any recognizable logic.

However, you can be sure that we will do everything to procure the desired material or suitable alternatives as timely as possible in order to be able to realize your project.

Outlook: Silver lining

We count on your understanding that due to price sensitivity we have reduced the validity period of our offer to a few days.

Market participants expect a gradual calming down around mid-2021. For all our sakes, we hope that more “normal” delivery times and prices will soon be the rule again.

Until then, please stay healthy!

Happy easter ….

…. please stay healthy!

20 years Ferrum Lasercut

Round birthdays and anniversaries are always a reason to look back. Even in Corona-Times….. although different.

Small celebration with a lot of distance

Actually, we had considered some time ago to celebrate the 20th anniversary of Ferrum Lasercut in October 2020.

Were it not for the pandemic. Because of the difficult situation, we thought it would make more sense to do without the big party.

Instead, the event was celebrated small and delicious with the employees and the appropriate distance. Just in time for the extended lunch break, the “style-your-burger” food truck drove up on a Friday in October and supplied the hungry colleagues with various burgers and salads.

Outlook 25…10

Provided that the Ferrum Lasercut company continues to develop well in the future, we are planning a really good party for the double anniversary … with customers, business partners and friends, employees, families and friends.

Because then Ferrum Lasercut will be 25 years old, 10 years since the takeover by the managing director Uwe Glasenapp.

We are working on this by naturally realizing you and your projects with creative and constructive ideas, lasered, bent, welded, with brisk deadlines and often with up-/downstream services.

Current situation

Your satisfaction is important to us. Now and in the future. Therefore it is necessary that we all stay healthy. This is why the tightened Corona concept was launched at Ferrum on November 2, 2020. In addition to the usual rules of conduct such as distance – hygiene – everyday mask and ventilation (AHA+L), it provides that outsiders are only allowed to enter the company to a very limited extent. If they do, then masks are mandatory on both sides. The employees from administration, sales and work preparation work in the home office, if possible. Production employees work in fixed teams and shifts that are clearly separated in terms of time, so that the risk of infection is minimized to a large extent.

We hope that these measures will enable us to get through the corona period without infection or illness and wish everyone good health.

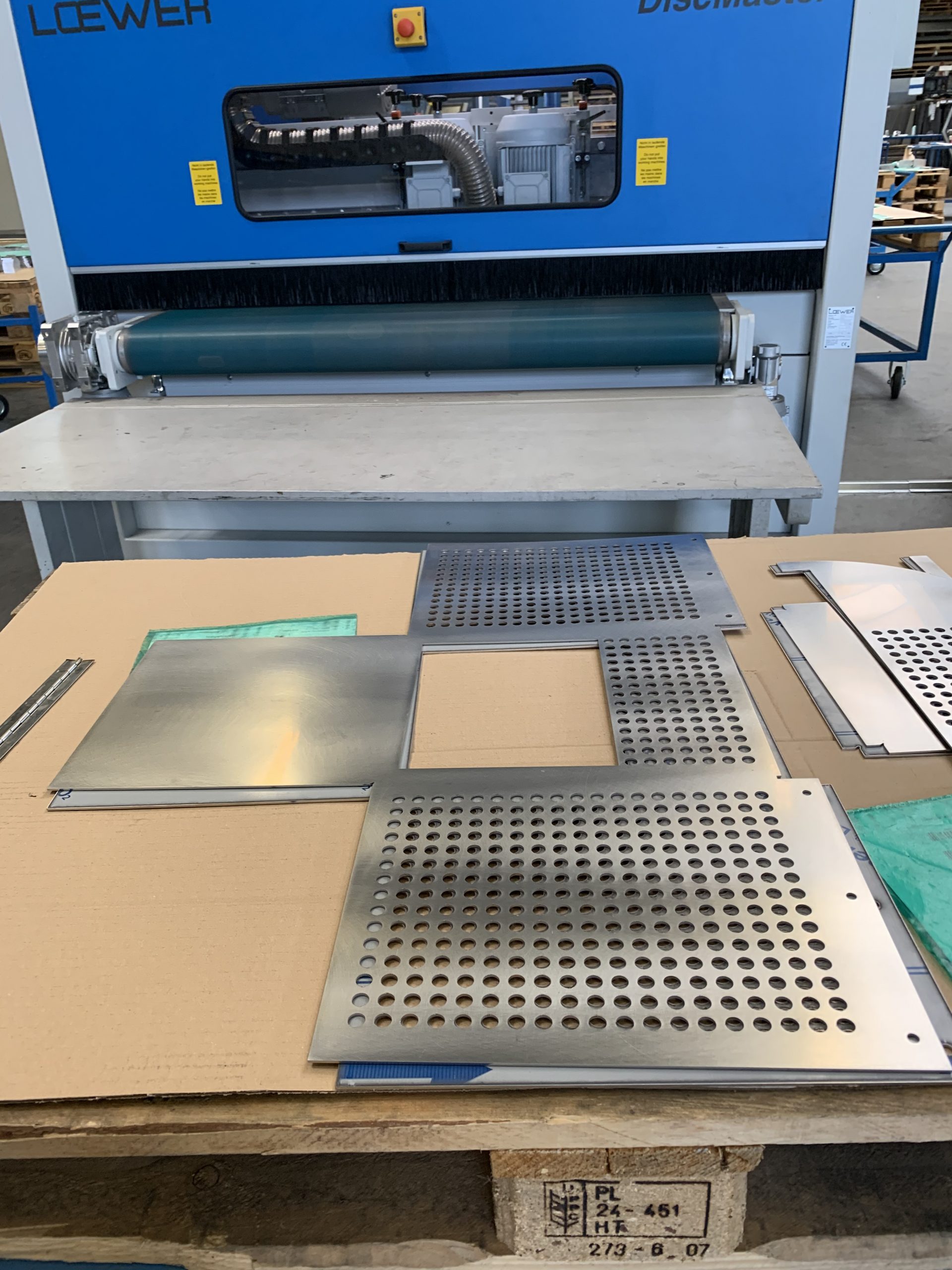

Deburring 2.0

Deburring Technology@FerrumLasercut

Depending on the type and thickness of the material, laser cutting produces a more or less pronounced burr, which is visually and haptically unattractive on the one hand. Above all, however, it makes any further processing more difficult and possibly even impossible.

Therefore, our customers expect cleanly deburred laser cuts, possibly with rounded contours. Until now, we have used a somewhat aged ERNST, a machine from the last millennium, which was still doing its job, but with increasing downtime and repair costs.

In order to meet the wishes and expectations of our customers even better, Ferrum put its money where its mouth is in spring.

time-saving – consistent – future-oriented

Since May 2020, two new deburring machines from Loewer and a suitable wet suction unit have been added to the deburring production area. In addition, the wet suction system enables an effective and safe deburring of aluminium parts.

The machine package consisting of DiscMaster 4TD, CrossMaster and suction unit now ensures uniformly deburred and/or rounded edges and inner contours for components made of steel, stainless steel and aluminium in dimensions from 20 mm to 1500 mm and a sheet thickness of 0.3 to 80 mm. It produces a uniform oscillating grinding pattern, if desired also on both sides. Foiled or galvanized sheets can also be processed.

Successful certification according to DIN EN ISO 9001:2015

On 16 September 2020, Ferrum Lasercut GmbH was once again certified according to DIN EN ISO 9001:2015 without major and minor deviations.

Quality and transparency for customer satisfaction

ISO 9001 certification is an effective instrument for us to control the quality processes in our company. All employees have internalised the principles and act with a critical view of the processes in their work areas. This of course benefits our customers and also helps us to win new customers.

By fulfilling the certification requirements within the framework of the regulations, our company confirms its commitment to quality and customer satisfaction.

Transparent procedures and the continuous improvement process within the company ensure a high level of service quality and enable access to new markets.

The current certification is valid until October 2023.

The “No Go” for this year’s mouse Open Day 2020

The Mouse Open Day was created for the 40th birthday of the mouse. Nine times since 2011 doors have opened for mouse fans all over Germany.

Doors behind which interesting things from all kinds of industries and organisations are hidden.

Doors that are otherwise closed.

Doors behind which mouse fans experience factual stories live on this day.

Ferrum Lasercut has opened its doors for the first time in 2018 and has brought an excerpt of metal processing closer to the small and big mouse fans. At the time, the response was so great among all participants that we were also involved in 2019.

We would have loved to open our doors again this year and welcome around 100 children aged between 6 and 12 years old together with their parents. Then came Covid-19 with its effects.

After examining alternative possibilities, the organization team at WDR came to the decision to postpone the 10th edition of the Mouse Open Day until 2021, because due to its special character and charm, the day only promises to be a real Mouse Open Day if you can meet in person, live and in color.

Postponed is not cancelled

We can understand this decision of the WDR and we look forward all the more to opening our doors wide at the 10th Maus-Türöffner-Tag next year and to giving many MausFans an insight into metal processing by means of a laser cutting machine, bending bench and welding equipment.

Stay healthy and cheerful, everyone!

VerA – is the name of the association of exhibition designers

As such, it offers a platform for professional exchange to exhibition creators and interested parties.

Exhibition and museum designers, scenographers, communication and trade fair designers are among the customers of Ferrum Lasercut. So it was quite logical for us to become an associate member of VerA.

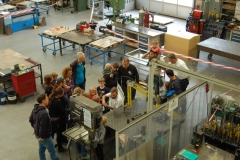

Within the framework of the regional meetings on February 19, 2020, we were able to take on the role of host in the series “VerA as a guest of …” and show a number of exhibition designers, lecturers and students what Ferrum is all about … and what is going on ….

If you can imagine it, then we can (almost always)* build it.

()* within the physical and material limits

Because ….. Ferrum can provide support at different levels and to different extents – depending on what is desired or required. Our experienced employees apply all their expertise to meet the requirements.

In terms of design, this applies to the constructive optimisation of assemblies, the transfer and preparation of drawings and files in the common 3D formats. In the next step we follow our core competence – metal construction – and give shape to sheet metal components, sheet metal assemblies and welded assemblies.

In this way, we create exhibits of any geometry: basic bodies, frames, visual and audio assemblies, monitor housings, light boxes, tables, shelving and guidance systems, steles, information boards and whatever else is to be realised in aluminium, steel and stainless steel.

Last but not least, we are happy to take over the project management including the downstream processes and, in particular, ensure high-quality surfaces.

Exhibits from our production can be found in renowned exhibitions and museums around the globe.

Please contact us if you would like to find out more, call us on 030 57797350 or send us an email at mail@ferrum-lasercut.de.

Sustainability – a question of attitude

The topic of sustainability is on everyone’s lips and Ferrum is also making its contribution

We cover 100% of our electricity needs from natural power.

The materials that are processed at Ferrum are characterised by their almost unlimited recyclability. Therefore, we recycle all steel, stainless steel and aluminium residues – separated according to material type – as well as their chips and dust, and feed them for proper recycling. In this way we contribute to the conservation of valuable resources.

The same applies to the products manufactured by us: at the end of their “life” they can be recycled without exception and melted down to form new basic materials.

We do not emit any pollutants, nor do we use any heavy metals, paints, chemicals or solvents.

In our manufacturing processes, we also take care to avoid waste in auxiliary materials and supplies or to recycle them.

We attach great importance to minimising any waste of resources. For this reason, we reduce paper consumption where possible and send quotations, order confirmations and invoices by e-mail as a rule.

Translated with www.DeepL.com/Translator (free version)

Certificate Green Power 2020 (only in German language available)

Top priority: Suppliers’ Day Berlin / Brandenburg

Uwe Glasenapp, Managing Director of Ferrum Lasercut GmbH, has often experienced that decision-makers in companies do not know what opportunities are available to them on the supply side in Berlin and Brandenburg. Therefore we were once again exhibitor and discussion partner at the Suppliers’ Day Berlin / Brandenburg on December 3rd, 2019.

And once again many a buyer/decision maker was surprised when he heard that Ferrum Lasercut is an almost perfect supplier and partner based in Berlin when it comes to single pieces, prototypes and small series made of steel, stainless steel or aluminium, which are to be lasered, bent, welded, provided with press-fit elements and provided with “surface”.

This year’s Suppliers’ Day Berlin/Brandenburg was well attended and so we were able to make new contacts and strengthen and expand the existing network.

Find new business partners with Speed-Dating

In addition to the exhibiting supplier companies, the IHK cooperation exchange offered the opportunity to define dates in advance so that concrete topics could be discussed. A whole range of potential customers and partners made active use of this opportunity.

The door opener day: factual stories live

The Door Opener Day took place for the first time on 10 July 2011 on the occasion of the 40th birthday of the mouse. Since then, mouse fans all over Germany have been opening doors year after year, behind which something interesting happens and which are otherwise closed. Companies, universities, craftsmen, theatres, town halls and farms offer young and old MausFans alike the chance to experience factual stories live on this day.

This year the door opener day took place for the 9th time. Ferrum Lasercut was on 3 October 2019 like last year. A total of 150 Mouse fans were able to experience live how ideas take shape in our metalworking company.

From the drawing to the finished mouse

The workflow from quotation to finished part was demonstrated in concrete terms using the example of the mouse – in this case made of 1 mm thick stainless steel. The children and their parents were given an insight into how an offer is turned into an order, how the drawings are prepared and nested in a machine-compatible manner so that the laser cutting machine can cut the contours of the mouse out of the metal with highly focused light.

At the next station – the bending bench or press brake – a bend was added to the flat mouse blank so that the mouse can stand.

Metalworking (almost) to touch

During the guided tour, the Ferrum Lasercut team explained further processing steps from laser post-processing and metalworking to give the young and old guests a small impression of the various possibilities of metalworking.

With big eyes, eagerly and with a lot of fun the children followed the single working steps and were allowed to take the mouse as a souvenir at the end.

The business location Lichtenberg

In November 2018, the image film of the business location Lichtenberg celebrated its premiere, impressively presenting the inner-city business location, its diversity and its potential – of course with the participation of some local entrepreneurs.

Link to the (German) Film: https://www.upl-lichtenberg.de/film/

Project business-oriented city marketing Lichtenberg

The urban district of Lichtenberg has experienced a considerable upswing in recent years. This is proven both by the figures regarding the increase in population (move to Lichtenberg) and the growing number of companies that have settled in Lichtenberg.

With the project “Lichtenberg in competition” new impulses for the present and the future are to be set by including the district’s past and thus making a significant contribution to the promotion of Lichtenberg as a business location.

The project is aimed specifically at the local economy, companies willing to settle in the district and actors who shape the business location Lichtenberg.

The aim is to improve the presentation of the district and the district profile and to improve and intensify the communication between the individual companies/actors participating in the project.

It is not the aim of the project to create a new “branding” for Lichtenberg, but to systematically improve the perception of the district together with the project participants.

(Source: www.beliber.de)

FRESHLY RECERTIFIED according to DIN EN ISO 9001

Since October Ferrum Lasercut has been successfully recertified according to the current DIN EN ISO 9001:2015 for the scope “Production of parts, assemblies and complex objects, especially laser technologies, CNC bending and welding”.

schaffen.erhöhung.dampflok

Ferrum Lasercut is now clearly addressable via “What3words”

More precisely: the incoming and outgoing goods department of Ferrum Lasercut.

what3words describes a simple system to describe every place in the world unambiguously.

“Normal” addresses are sometimes imprecise or ambiguous. Street names exist several times, as well as many areas where there is simply no address system – from slums and informal settlements in cities to the park where you want to meet your friends or a precise place where you wait for your taxi.

Triggered by their own bad experiences the 3 founders of what3words 2013 have started to develop an alternative address system based on the unique use of words. For this purpose the world was divided into squares of 3m x 3m and each square was assigned a unique 3-word address.

With what3words it is possible to locate any place precisely and pass on the address faster, easier and more unambiguously than in any other system.

In addition, the use of words means that people who are not so technically proficient can find and understand 3-word addresses more easily than a postcode or GPS coordinates. They can communicate the address faster, more accurately and without ambiguity than any other address system.

This changes the way people and businesses communicate about places. What3words is now available in many languages. Depending on the language version what3words uses a word list of up to 40,000 words.

YOUNG DESIGNER GUEST AT FERRUM

On November 2, 2017, 15 students of the product design course at the UDK visited us on an excursion. In the third semester, the young men and women, under the direction of Prof. Holger Neumann, are dealing with the material metal, construction and production technology.

We encounter metal in many areas of everyday life: in industry as well as in some trades, in interior/architecture, in interior design, in trade fair and exhibition construction, in the fine arts and in art on building projects.

As a term paper, students work on a design that will take shape with the help of Ferrum Lasercut. Ferrum will provide the sheet metal (0.5 square meters of sheet steel, 1mm, per person) and the laser capacity. In the first quarter of 2018 the designs will be presented and evaluated at the UDK.

WELDING TEST: FRESHLY RECERTIFIED

In October 2017 the welding certificate for Ferrum Lasercut was successfully renewed and is now valid until 2020, allowing us to weld statically stressed components up to 20 mm thick.

MetalZert-DIN1090-Certificate (only in German language)