Welcome to Ferrum Lasercut

REALISE YOUR PROJECT IDEA IN SHEET METAL WITH US

Competent, individual, fast and reliable from one source.

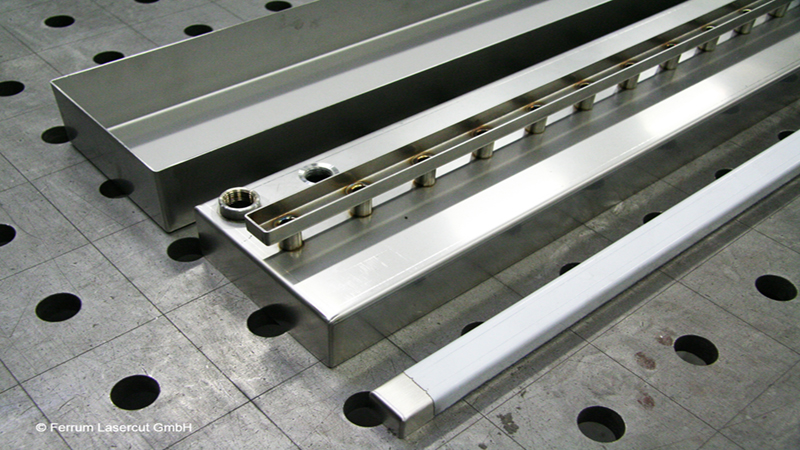

Ferrum Lasercut is your idea implementer for everything to do with sheet metal.

We laser, bend, weld and do just about everything to make your project take shape so that it come true.

______________________________

We moved. Now you’ll find us in

BRUNO-BÜRGEL-WEG 142-144, 12439 BERLIN.

Truck access via Ostritzer Straße

The telephone numbers and email addresses will remain unchanged.

For all those who would like to find the address using “What3words”…. Here is the new address what3words: ///spannend.ersehnten.Eintritt

______________________________

JOBS

We need support and are therefore looking for an employee for the locksmith’s shop. For more information please go the GERMAN job description

______________________________

SUSTAINABILITY

Of course, the subject of sustainability does not bypass Ferrum.

We make our contribution to resource conservation as follows:

- We cover 100% of our electricity needs from natural resources.

- The materials that are processed at Ferrum are characterised by their almost unlimited recyclability.

- We therefore recycle all steel, stainless steel and aluminium residues (as well as their chips and dust) – separated according to material type – and send them for proper/professional recycling. In this way we contribute to the conservation of valuable resources.

______________________________

Knowhow from practice for selected startups

MotionLab.Berlin is an institution for hardtech startups.

Recently some selected startups startet in the accelerator program.

If you want to know about Ferrums role in the programm (or better to say: Uwe Glasenapps) please read the complete article in news.

______________________________

PREMIERE!

Ferrum Lasercut GmbH exhibits at the MUTEC in Leipzig.

MUTEC is the International Trade Fair for Museum and Exhibition Technology.

Here decision makers, planners and employees from museums, galleries and collections as well as responsible persons from science centers, theaters, stages and public institutions meet. They use the fair as an information platform with regard to the current state of the art in exhibit construction, climate and measurement technology, ticketing, equipment and much more. For further information please read the complete article in news.

Industry

Ferrum Lasercut produces from batch size 1 piece, creates prototypes and (small) series according to common industrial standards. This is made possible by modern construction methods, perfectly interlocking production processes and complete documentation.

Craft

Far away from serial production, at Ferrum Lasercut every project is basically considered a new challenge. If at one moment bed bases are manufactured in small series, in the next moment it can be railing constructions and underlay/compensation plates for the roof truss, parts for shop fittings, garden architecture or large-format cubes for exhibition stand construction.

Artists and Creatives

There are no or few limits to the imagination. This is exactly why custom-made products for the (Berlin) creative scene as well as “Kunst am Bau” projects are not uncommon with us. Well-known artists have already turned their works into reality with our manufacturing expertise. These works of art can be found throughout Europe. If you can imagine it, we can produce it – at least most of the time.