Ferrum Lasercut as supplier for special machine construction

Ferrum Lasercut offers unconventional, individual solutions for special machine construction

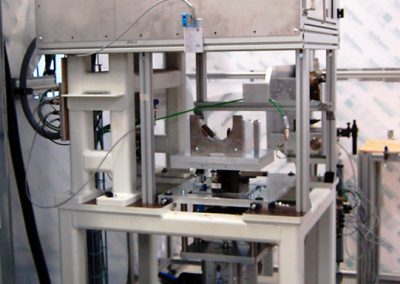

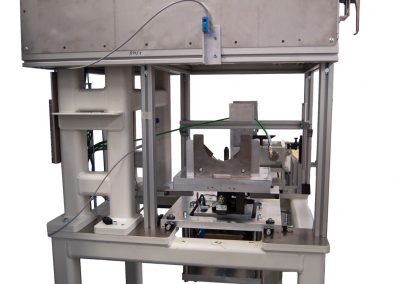

In order for machines to perform their work accurately, reliably and permanently, either as stand-alone units or in production lines and robot cells, they generally require a solid base frame.

Boschen & Oetting Automatisierung GmbH realizes automation lines mainly for the automotive industry and the pharmaceutical and lighting industry from a single source – from the conception of the system to the design, production and installation as well as the service of the production line. For housings, underframes and mechanical components like fastening devices Boschen & Oetting trusts in the know-how and experience of Ferrum Lasercut GmbH. In addition to that common constructive optimization-

The basis for the cooperation in partnership is the high degree of flexibility and the short implementation times.

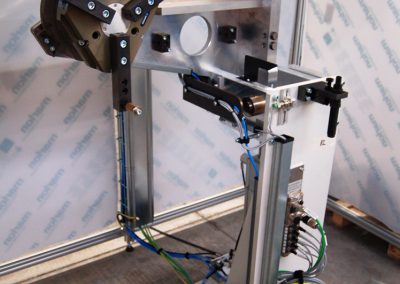

This project involved the substructure of a marking unit in a robot cell. Designed as a welded assembly made of square steel sections and fully assembled and wired, nothing stands in the way of intensive use within the production line.

- Customer: Boschen & Oetting Automatisierungs GmbH

- Metal Works: Ferrum Lasercut

- Project: Substructure for marker machine

- Materials: Steel square profiles, welded, powder-coated

- Link: www.boschen-oetting.de